One of the best methods of measuring how well a production line is running is Overall Equipment Effectiveness (OEE). To help explain how OEE works, below is an example.

Example

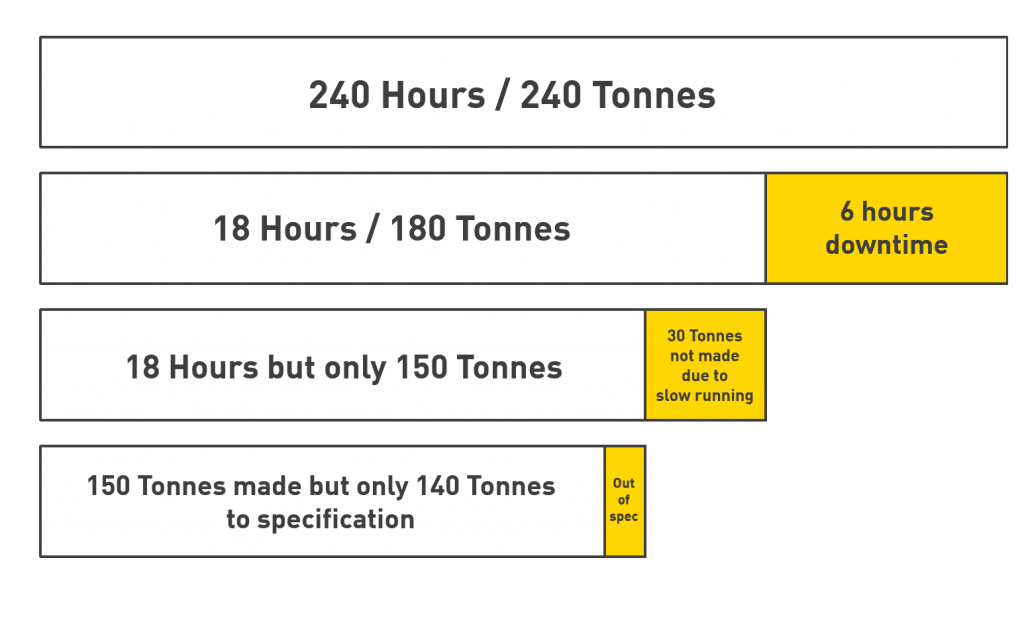

I have a plant that I know runs at 10 tes per hour when everything is great. It runs 24 hours a day. That means in theory I can get 24 hours multiplied by 10 tes an hour, or 240 tes output in a day.

This is great, but during the day I had to shut down for six hours. Two hours were because I ran out of a raw material and had to get an urgent delivery. I also had to stop in the night for three hours because a bearing had collapsed and I needed to call someone out to repair it. Another hour was lost changing from one product to another. That meant instead of 24 hours running I only ran for 18 hours. The best I could now get was 180 tes.

The following morning when I sat down with everyone we had only made 150 tes. Why I asked? I was told the machine is running slower than normal. We had been getting a number of quality issues and to try and reduce them the machine had been slowed down.

I was then told that we had made 10 tes of ‘out of specification’ material. We could probably blend it, but still it was out of specification. So at the end of my 24 hour day I had 140 tes of in-specification product, when I had the potential to make 240 tes.

OEE is calculated as the quantity produced that is in specification, divided by the total quantity that could have been achieved if everything went perfectly. In this case 140 / 240 = 58.3% (OEE is normally expressed as a percentage).

World class companies measure Overall Equipment Effectiveness and aim to achieve results in the range 85-95% depending on the nature of their production. However some factories achieve as low as 35%.

OEE is a great tool for measuring and understanding how well a plant is operating. It also helps us to understand if we are improving or not. One final comment – 100% OEE is achievable within a shift or day but not in the long run. Even with the most reliable plant, just like your own car, it does need to be routinely serviced.

For more information or advice on Overall Equipment Effectiveness (OEE) and measuring how well a plant is operating, please contact Steve on enquiry@w-l-p.co.uk